Perforated metal (also known as perforated sheet, stamping plates, or perforated screen) is made through the metal stamping and sheet metal manufacturing process. Sheet metal materials include steel, aluminium, stainless steel, bronze, brass, titanium, and so on.

Technical terms:

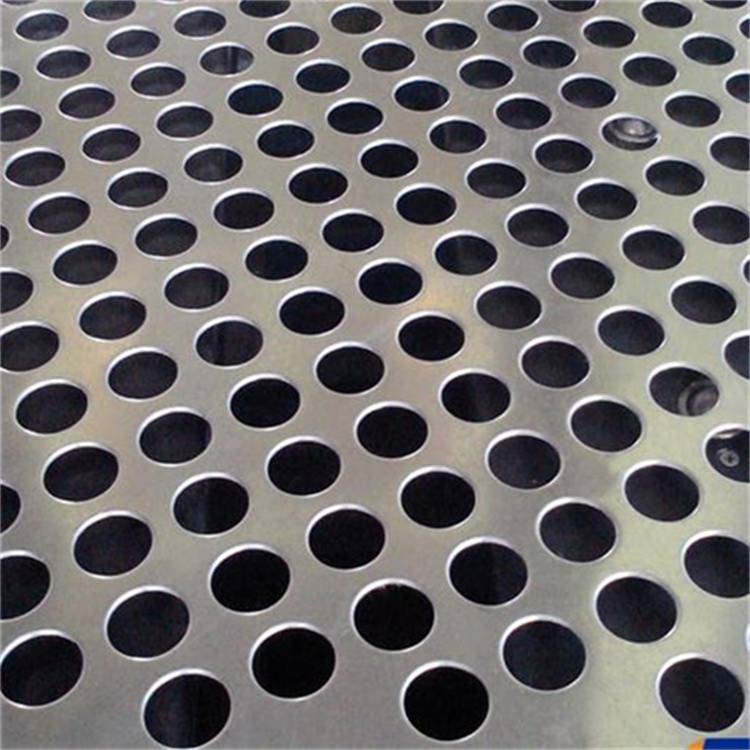

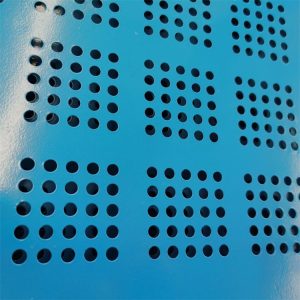

Staggered Pattern: Holes are aligned in staggered or nested orientation. A staggered perforation pattern can provide the highest open area.

Straight Pattern: Perforated holes are aligned in straight rows and columns.

Unfinished Ends: The end perforation pattern is not solid and appears rough and incomplete at the end of the sheet.

Margins: Area on the side, ends, or inside the perforated sheet without perforations

Safe Side Margins: This type of margin is achieved by perforating the material all the way up to the edge but not on or over the edge

Perforated Tool/Tooling: Interchangeable die sets: pins/punches, die plate, stripper plate,

and punch holder used on the perforating presses to perforate the various perforation patterns

Hole Size: Diameter measurement of the perforation shape; measurement from side to side

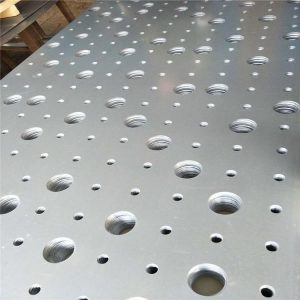

Finished Ends: The end perforation pattern is solid and appears uniform or complete at the end of the sheet

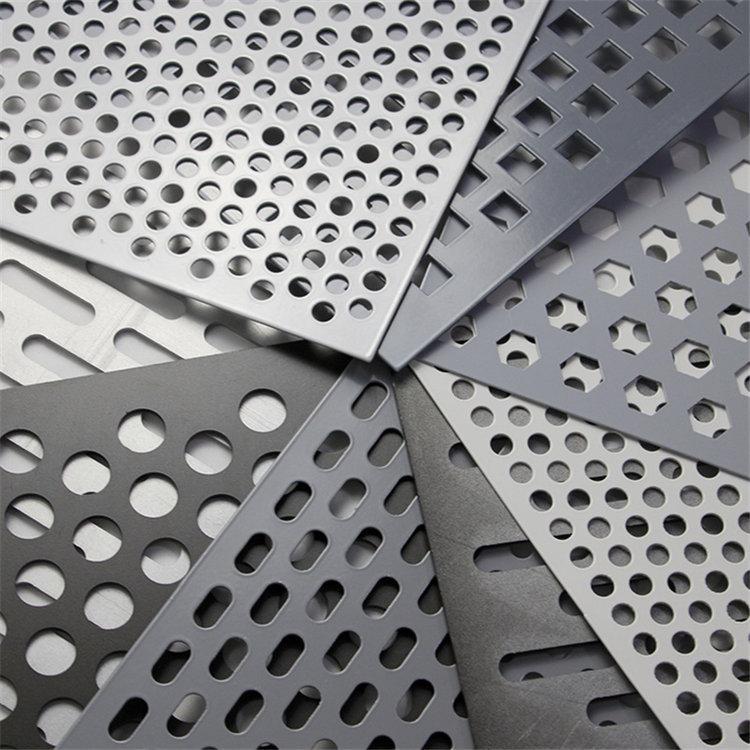

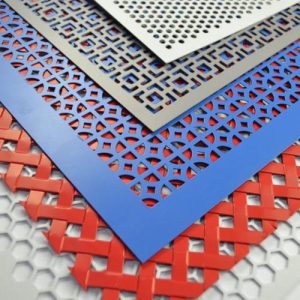

The hole shape: Round, long round, oval, square, diamond, triangle, scale, hexangular, slot etc.

Specification: We can punch the metal sheet from 0.1mm to 10mm. In general,

it is advisable to use a hole size equal or less than the material thickness.

Your special requirements can be available

Applications:

Interior Design, HVAC, Noise Control, Security Ceilings, Sunscreens, Building Facades,

In-Fill Panels, Ceilings, Furnishings, Stair Treads and Risers, Screening and Fencing

There is an impressive variety of possibilities for the use of perforated products, which are found in nearly all branches of industry

Food Processing: for bee hives, for grain dryers, Wine vat, And also for fish farming, hammer mill screens, silo ventilation, sorting machines (screens and drums), threshing machine screens, and for winnowing machine screens. Bent and folded perforated sheets as elements for conveyor belts. Stainless steel juice channels for wine presses. Brewing Industry – Malting Floors, Hop Screen. Food Industry – For vegetable and fruit presses

Automotive industry: Ventilation for tractor engine, Casing, Ventilation grid etc